Hollow Ebony Hoops

Our customers work with us to create lasting pieces of jewelry that enhance their fashion sense and give them a reason to dress well. They feel good and look good to themselves and to others, and isn’t that what dressing up is all about? We create a persona with flair that pleases us and brings a smile and admiration from others. We lift people up around us, not just ourselves, when we celebrate beauty.

Hollow ebony hoops with a satin finish.

This customer has flair in spades. So it was a technical challenge to create these extra large, elegant hoops so that they could be worn comfortably for several hours.. We lightened them up by designing them hollow. We also made them with an ear clip, no post, so that they were versatile and could be placed, to the customer’s liking, either higher or lower on the ear lobe . The final size of the hoop was just under two inches, and half an inch wide.

At, 1.7 inches tall by .5 inch wide, the hoops make a fashion statement but not too heavy to wear.

As a jewelry workshop our goal is to work to a small scale. Finding small holding devices is a challenge. When Gregore’ found these tiny vices we were very pleased though transacting with overseas was somewhat of a challenge. When the company had a sale though we bought a second one because we aren’t quite ready to give up this line of work!

The tiny vice came from Germany. The Hoop is a CAD design

cut with the CNC

Here is a video of how the hoop was held and cut.

The hoop was carefully thought out so it came together without weakening the wood or loosening the metal parts.

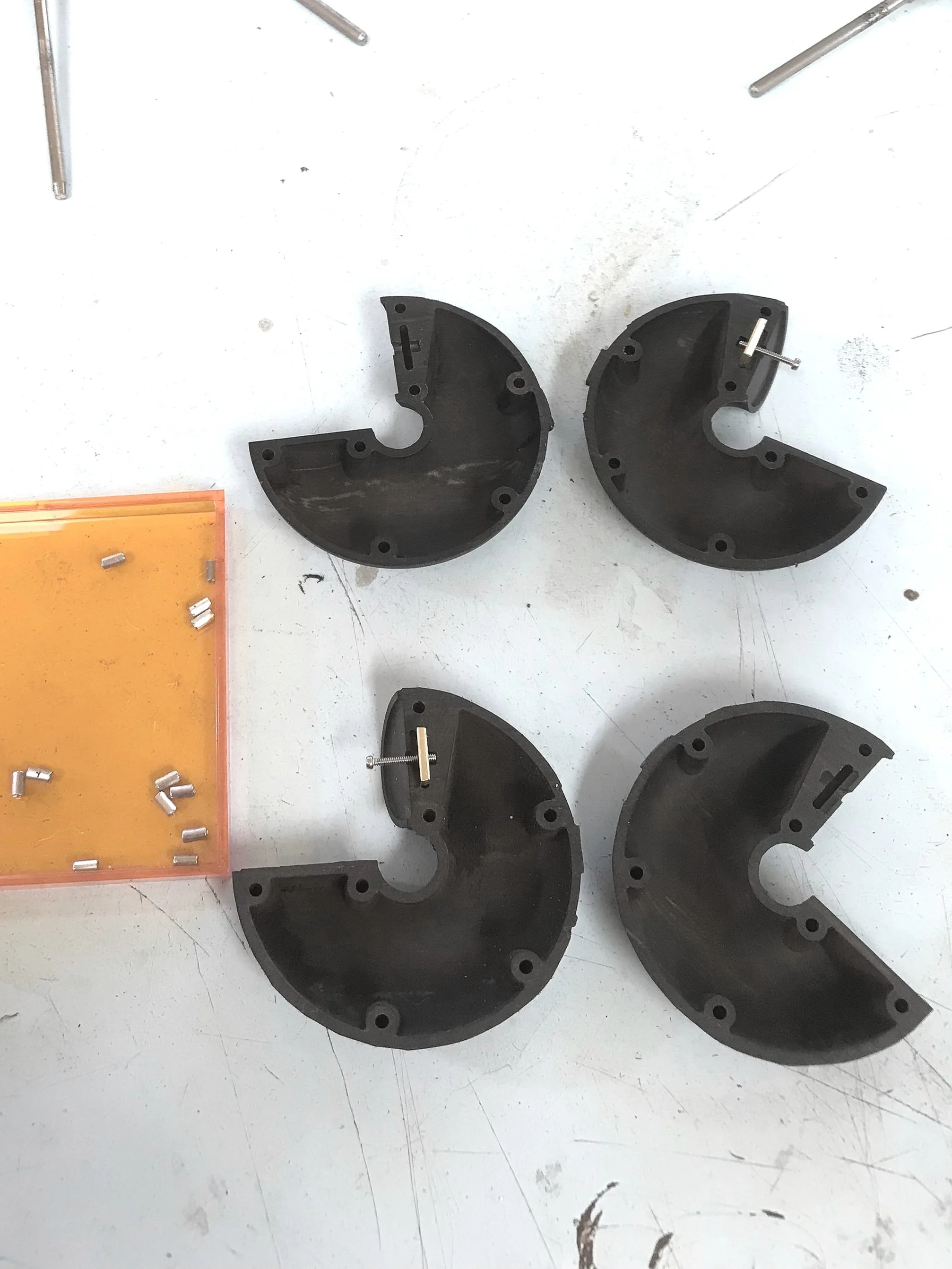

This picture has the clarity to show the slot that will hold on the cap with its clip. The circles will have steel pins that join the two halves with glue. Notice how the wood was left thicker in all these parts so that the hoop would not break easily but rather withstand the test of time.

In the daylight the shape is more visible. Notice the wasted material in gregore’s hand so the vice has something to grip while cutting.

The video shows how lustrous ebony is and how fine a finish is left from the carbide burs. This type of smooth surface is accomplished with the small cutting steps programmed into the tool path of the CNC.

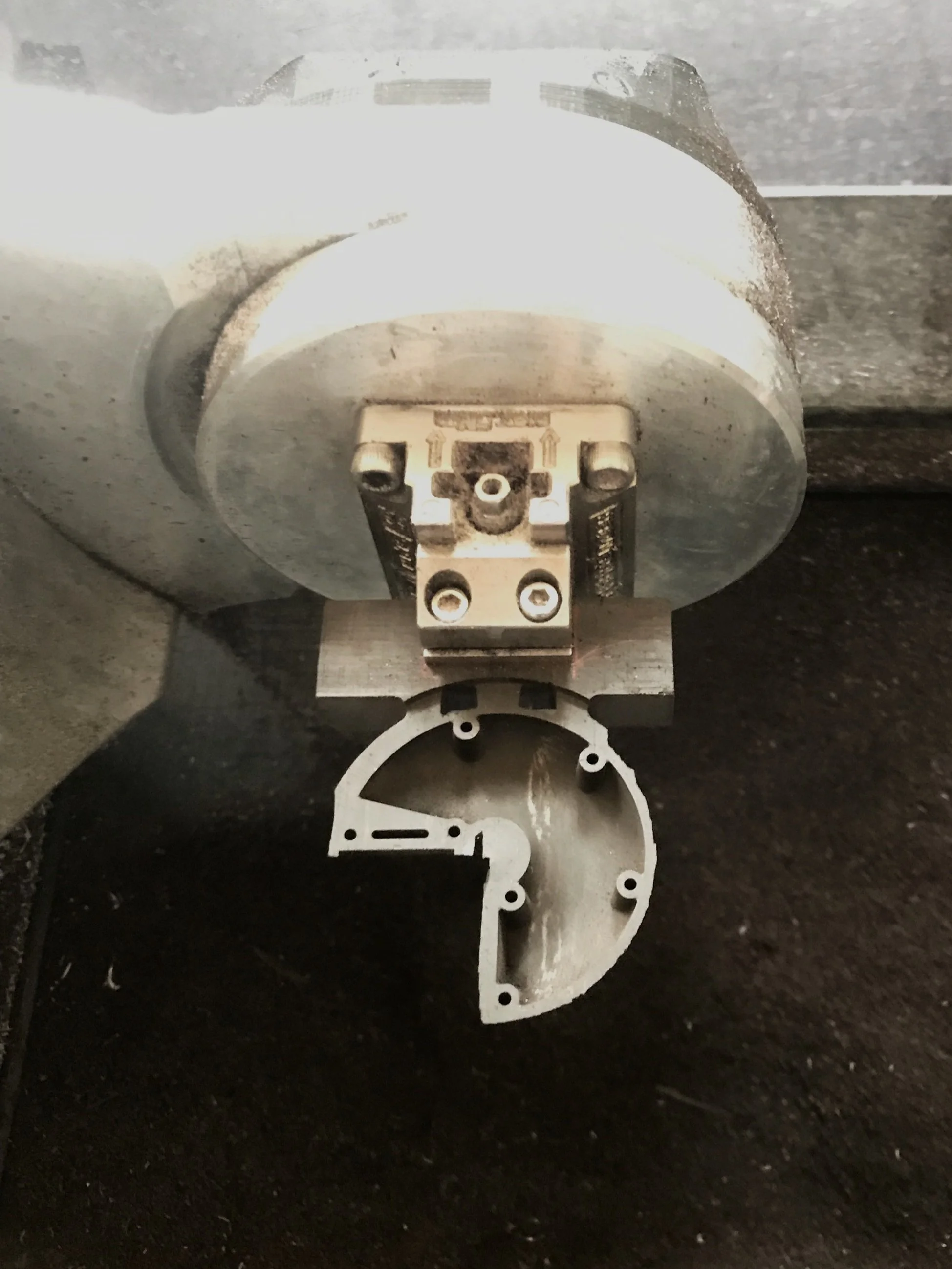

A steel screw is inserted into a threaded brass plate that is securely held inside the wood. This screw will later hold the cap and ear clip. Steel dowel pins will be glued inside the holes, holding the two halves securely.

The steel dowels fit inside the holes in the hoop, and the bar that holds the screw lives securely in its pocket.

Sorry for the poor image. A closeup of the screw, plate and slot in the hoop.

Our custom alligator clips holding the two earring halves together while gluing. You can find these clips for sale under the tools tab.

As you can see by the raw edges of the wood hoops there is considerable work yet to be done to have the finished hoop look like it does in the image below. The finishing steps are first to file the rough edges, followed by sanding with progressively finer sanding paper. A 600 coarse grit leaves a nice dull and rich luster. This matt look hides the center glue seam beautifully. Wood is very forgiving and a pleasure to sculpt.

Closeup of the steel screw and sterling silver cap.

Closeup of the alligator tongue which grips the ear when worn.

Closeup of the back of our custom clip.

Closeup of the inside of the custom clip.

The finished hoops looked fantastic on. Our customer enjoys wearing them and we hope that if you like this fashion sense that you will inquire about other designs.

Our custom felt bags that protect the hollow ebony hoops, and some of gregore’s whimsical brooches.